Waterwell project update 2006

Update complete - 15 April 2006

Apologies to anyone with a dialup connection: all the pictures are 500 pixels wide and so will be very slow to view.

Practical note

It only needs 50 people to donate the equivalent of one year's water bills to provide water for 1,250 Zambians for years to come! Once the startup costs are covered it only takes a further 15 donations for the next 1,250 recipients ...

Chifubu compound, in north-east Ndola, is home to 60,000 people, many of the poorest don't have access to clean water - what use is one pump, or ten pumps, or ... ? Take a look at 'The daffodil principle' for an answer.

Semantic comment: the word 'compound' is used to describe the Zambian equivalent of a UK housing estate or housing area. But these compounds are typically for the poorer residents with very basic homes on a small plot, some of the better ones having electricity, rarely having a tap or toilet indoors. The poorest are built of mud bricks (that get eroded by the rains) and instead of corrugated iron roofs have grass roofs. These compounds are quite distinct from a rural village setting which has a well defined centre without precisely defined dwelling plots.

From the update of the previous year ...

Thu 28 April 2005 - Received an email from Andy that describes a new design of hand pump:

"We have an opportunity to introduce a new design water pump into the villages- one that uses a revolutionary new design that could be manufactured in-country and installed in existing or new wells. The design is very light weight and can be easily maintained by the women of the community. The attached .pdf file has a description of the pump.

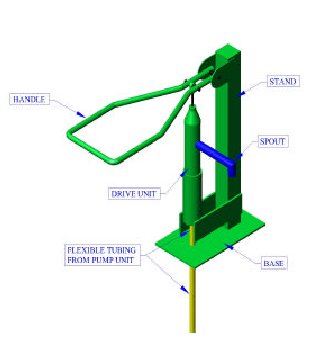

The pump works by hydraulic action. When the pump handle is pushed down, water is forced down the pipe compressing the pump spring. When the handle in raised, the spring forces water up the flexible riser and out the spout. The thing that makes it different from regular pumps is that the well head can be at a distance from the pump, and that simple wrenches are the only tools.

Richard Cave (paper's author) is keen to have this pump introduced into third world countries where there is a desperate need for clean uncontaminated water. Zambia could be one of the target areas and it could be manufactured and installed by local people. The simple rugged lightweight design and ease of maintenance makes it an ideal water pumping system. It can be maintained using a few simple hand tools and locally available parts. Using a single flexible line from the downhole pump to the remote drive unit/outlet remote from the well bore contamination of the well from users can be minimised. This pump has been tested locally for over 1400 hours without problems and works to depths of over 100 feet."

The Awassa pump

Monday 20 March 2006 - Met the Canadian pump couple at Heathrow en-route to Lusaka. As arranged I had a Daily Telegraph under my arm (in true British spy style), but Richard recognised me from the many pictures on my Zambia and waterwell web pages! So with two hours at Heathrow and a ten hour flight we got to know Richard and Adele and the story of the Awassa pump. Awassa is the name of a town in Ethiopia where the designer of the pump first had the idea of a hydraulically activated hand pump for poor communities.

Tuesday 21 March 2006 - Met at the airport by Tony & Josie, from the farm, who 'just happened' to be picking up their daughter from the same flight! Richard and Adele were met by a Canadian friend of theirs, Howard, who was in South Africa on another project and came up to join them. So between them the four of us were given a lift to Ndola bus station where we were 'mobbed' by guys wanting us to choose their bus for the four hour trip to Ndola. After the necessary haggling we managed to get cheaper seats (without paying any extra for luggage - and what with the two complete heavy pumps there was plenty of luggage). But it was an hour and a half in a rather warm cramped coach before we got under way - coaches don't go until they're full. When we did get going the passengers were invited to volunteer to pray for the journey, and so someone prayed, and off we went. But before leaving Lusaka the driver decided that one of the tyres needed a little more air! So a diversion for inflation. I'm convinced our driver used to be a train driver: I've never travelled this fast on a coach - when obstacles appeared in the distance he blared the multi-tone horn and kept up the speed! But for all that he only overtook when appropriate.

On arrival at Ndola I got my mobile SIM card operating again at the Celtel shop and phoned the farm for transport. This duly arrived and after a bit of to and fro-ing with transport arrangements for Richard, Adele and Howard we set off for the farm. But this wasn't straightforward - Gary, the driver from the farm, hadn't topped up with diesel so we ended up pushing the old pickup into a petrol station!

The evening arrival at the farm was beautiful, so peaceful, so quiet, so lush and so big.

Our accommodation: en-suite, fridge stocked with drinks, its own verandah, was a lovely place to end a long journey after a lovely meal.

Wednesday 22 March 2006 - First morning on the farm and treated to breakfast laid on the table on our own verandah. Total bliss ... with a very long view across the unspoilt valley to the hills beyond ...

... beautiful.

We had arranged to meet later that morning with the 'pump team', Richard, Adele and Howard, and also with the 'main man' Kirk, from Santa Maria Vineyard (who set up the Seeds of Hope International Partnership charity - SHIP), at the Savoy Hotel.

Not quite the same standard as in England (or anywhere else, for that matter!). After toasted sandwiches at Paterson's bakery we all went to look at the new bore hole being drilled at the Isubilo house.

This house is for orphans in the care of a house-mother just down the road from the Isubilo Centre in Chifubu, a district of Ndola city.

Andy Patching, director of Isubilo, then gave a guided tour of the centre for the whole party. Pictures here of the maize mill.

Next stop, the SHIP house and a quick glance at the sand filters manufactured on site.

We planned to start the first Awassa pump installation next day at a site in Mapalo, a very poor district in west Ndola.

Thursday 23 March 2006 - Nothing seems to happens quickly in Zambia: arrangements, shopping, pick-ups all seem to take longer than they should! All of us eventually, at lunch time, were at the pump site along with a local team from SHIP to start the pump base. The existing well had been in use with an India Mk II pump which needed major work done on it. The location was chosen as it is in the area of the new Vineyard Church plant of Mapalo Vineyard whose pastor, Francis, is very involved with Kirk and SHIP. Francis has overseen many of SHIP's well, latrine and sand filter installations.

The small piece of of pipe sticking up is the existing bore hole.

Kirk had other business to attend to so there we were: Richard, Howard and myself plus the local Zambian team, a pile of sand and stone, bags of cement and a pump to install ...

Having never done this before (let alone laid a concrete pump base) Richard sought to lead the way knowing what was required for the new pump and needing some common sense and practical help from the two of us and the Zambians, who dug the holes and mixed the concrete!

What looks like small drum with a lid on it )above) is a hand-dug well where the water level is just two metres down! (More later ... )

How many men does it take to... ? The well lining had to be cut shorter.

The pump unit goes down the well and the drive unit is bolted to a concrete base, on the right, enabling the two parts to be serviced independently.

Now how big is the pipe?

And then it rained ... it fell down ...

... so we sheltered in the house right by the well ...

Grandma at the back there keeps appearing in the photos ...

Smile?

Right!

Now just remember that ...

The father of the house, Steven, who, it turned out is a bricky, and came to the rescue when it got to the cement laying a bit later.

So where do the bolts go then, Richard?

The hole had got rather full with the rain ... now baling a well usually means emptying the water from the inside ...

The base was done - complete with its six stainless steel bolts buried in the concrete. The well head was then left to Steven to build a small brick enclosure to just above ground level ... so off we went.

Friday 24 March 2006 - Having decided to let the first phase of the concreting to get set, the Mapalo site was left till next Monday/Tuesday when the pump itself will be installed.

The second Awassa pump is to be located at Francis' home (next door to the house which is SHIP's latest acquisition). There it is to be used for field trials under close supervision, and later, it is hoped, for pump training. Today Richard is to be sorting out the best way to fix the drive unit (the part at the surface, the visible assembly with the operating handle). The pump unit, the part that actually pumps the water, is positioned near the bottom of the well.

Meanwhile we (Abbie and I) had a lovely relaxing day, especially enjoying a guided tour around the farm - with Abbie and a pony cart ...

So why not do it in style?

She was let free to run (with no reins!)

Whoa, whoa ... stoooop!

We looked around the seven hectares of bananas - the lowest portion is removed to promote growth in the bananas already developing ...

Can I have a ride?

There is also a spring ...

... and beehives ...

... and lots of jatropha planted for its oil for biodiesel ...

Abbie got to help with the donkey!

Then disaster! We learnt that at about 5am that morning that the six stainless steel bolts, sunk into the concrete for the pump base, had been dug out and stolen! Richard had then gone into town to Ndola Engineering, who had been commissioned to produce the steel base plate base for the second installation, to make a more secure set of longer bolts on deep-mounted plates that would be buried deeper into concrete. However much a difficulty this posed it was a sort of 'blessing in disguise' in that it showed Richard, first hand, what the security issues here are really like and how this affects future designs and modifications.

Saturday 25 March 2006 - Another easy, relaxing day ... !

Sunday 26 March 2006 - Andy & Eira's church was hosted at the farm - complete with a meal and lots of fellowship and a swim for the children ...

Richard, Adele and Howard came and were given the farm tour plus a good meal and joined us 'in church' in the afternoon.

Michel showing Howard the cooled banana store.

Monday 27 March 2006 - Richard got the new base plate and brackets and we had another easy day with a brief look at the recently purchased houses on the nearby Kaloko compound (featured in last year's project - very poor and severely lacking water).

One of the three houses purchased by Lifespring to begin the process of starting a school for the AIDS orphans ...

... and a typical Kaloko home.

Tuesday 28 March 2006 - To Mapalo in the morning to concrete in the new bolts and plates for the second attempt at producing a base for the first pump. This was achieved successfully with Steven's help as he had a hammer and chisel!

So who's doing the work here then?

The completed well head.

But it needed a little modification ...

Meanwhile Grandma keeps her eye on things ...

... and others nearby ...

Job done, the second set of bolts in place ...

... and hidden!

The Awassa pump

In the afternoon Richard gave a demonstration of the pump's maintenance to the SHIP bore hole team who had just finished the bore hole at Isubilo's sheltered house for orphans.

I get to play ...

Wednesday 29 March 2006 - After a slow start to the day Abbie and I borrowed a vehicle again and went to the SHIP house. The planned morning installation at Francis' house couldn't take place because the base plate wasn't yet ready (no surprise there then). I took a look at the well head to discover that a family of frogs was living in the well!

So, the first of the Awassa pump installations finally happened! We went to Mapalo for the third time, confident that the concreted-in bolts would still be there and the installation could proceed ...

All hands to the pump!

There was a delay as we had a little difficulty with the inflexibility of the pipe, trying to get it to curve up below the drive unit without it kinking (at ground level). This done, the drive unit was duly bolted down and assembled. This just left the pump unit, all two metres of it, attached to the pipe and support rope, to be lowered down the well.

Getting the pump unit ready ...

... and down it goes ...

... and stop ...

At last, 12 years after Larry Dillon had the idea for this pump in Awassa, Ethiopia, it was ready to try out in the very type of community it was designed for.

The pump was primed (being a hydraulically operated pump the whole thing has to be full of water before it can work), and the pumping started.

Lo and behold, out came the water! A very exciting moment!

Kirk and Francis working well (!) together.

It was tempered by the problem of very muddy water being pumped out (hence my exclamation of 'a hot chocolate machine'!) On a technical note: a well should be 'developed' before being put into service: all the mud and sand should be baled out first before operating a pump in it. We didn't have the facility of doing so. The well was therefore getting cleared by the new pump - not very good for the pump.

Thursday 30 March 2006 - Went solo to the SHIP house and to see the second pump installation next door at Francis' house.

Tried an interesting cucumber-like vegetable/fruit ...

The sand filters were coming on ...

... and a container had been purchased ...

... so how do you get that by the side of the house? With difficulty!

It got there in the end! And there was a welding job to be done ...

... now it's plugged in ...

As the pump at Mapalo had stopped working the Canadians went back to Mapalo with some pump spares to get it fixed. They later returned and reported that the pump had got completely gummed up with sand and mud but was now running clearer and repaired.

After lunch Francis' pump installation was started - but not before I had successfully 'fished' the frogs out of it! Even though the existing bore hole is 27 metres deep the water table is just 2 metres below the surface. A family of frogs had taken up residence and I thought it necessary to fish them out of the six inch pipe before the 2 metre pump unit was dropped down on top of them!

Richard used every opportunity to train the local team in the pump's construction and maintenance. In this case one of Francis' team, a college lecturer and Stephen (from the Mapalo pump site) were shown the ropes (literally).

The pump drive unit was fixed to the newly fabricated base plate and the pump unit was assembled and then the heavens opened! The storm had been approaching for the previous half hour, the lightning approaching in two directions, and the cloud seemed so low as to be just above the roof tops ... another proper tropical storm of dramatic proportions rarely seen at home. And it just didn't stop! So rain stopped play until just before dusk (which is at about five thirty, then there is barely an hour until complete darkness), but Richard managed to get the pump installed, but not yet primed and tested.

One thing that hasn't really come out so far in this update is that all through this week there has been a surprising number of people meeting people through this visit of ours. Kirk has been put in touch with yet more contacts; the lady who runs CINDI (children in distress) has visited Isubilo; Peter, an American farmer visiting Zambia with Kirk, has toured the farm; the Canadians have visited Isubilo. Interestingly I felt that God has said that so far as the pump project is concerned, "The job is done" - in that the Awassa pump is now in Africa; a pump team is in place in Ndola (that was happening anyway) and Isubilo has a bore hole for its sheltered house. This is not to say that more is not needed but that what was to happen, has happened! Another important activity has been the training/demonstrating that Richard has been providing at any and every opportunity when the pumps have been worked on.

Friday 31 March 2006 - As Richard and Co were delayed in arriving at Francis' well they called to suggest that I get Gerry's pump team to prime and test it (Gerry from the States has been operating the drilling rig with a local team managed by Francis). This was duly done, so before Richard arrived the pump was producing quite reasonable, but not yet drinkable, water (a well should be 'developed', drawing water out till it runs clean, before a hand pump is deployed).

The Canadians and their host, Mary.

The Canadian group had done all they could for now and were overdue to leave, so we said our goodbyes. A great job had been done in testing out the idea - a number of modifications had been suggested which were noted for version 3!

I ran the pump for a while to see if I could get the water a little clearer ...

Saturday 1 April 2006 - We're getting through our rather good books ...

Sunday 2 April 2006 - Went to the 'House of Prayer' pentecostal church followed by an hour's trip to Nsobe game park for lunch.

An ox cart en-route ...

That's me in the middle!

Monday 3 April 2006 - As Michel (from the farm) had expressed an interest in the pumps it was arranged that he and I would check out the two locations and see if all was well(!)

The Mapalo pump was not working.

We needed to go to the SHIP house to get the tools and pump spares and so checked out Francis' well also. It was OK and running nearly cleanly. As both the adjustable spanners had 'disappeared' from the kit left by Richard we returned to the Mapalo site via a hardware shop having bought a couple more spanners.

Grandma and Michel.

Michel and I set-to and withdrew the pump unit from the well and dismantled it to discover it badly blocked with sand. It was very difficult to remove the the spring stop at the bottom and even more difficult to withdraw the dual-action piston assembly ... it had to be repeatedly dropped to cause the piston to appear at the bottom for its withdrawal.

This shows the wear caused by the sand being rubbed by the spring.

This done, the leather cup seals were removed and washed. When reassembling we were unable to unscrew the upper cylinder tube from the lower cylinder to facilitate the reinsertion of the piston.

So, more by luck than judgement (and a big shove) it was returned. The ease of maintenance (if the tubes could be unscrewed) and withdrawal/return to the well nevertheless make this a pump a winner! However in practice this would only work well if a much more flexible pipe is used (thereby solving the kink problems encountered when first installed).

Then to the drive unit (above ground): it too was gummed up with sand - especially around the outside of the cylinder insert.

I wonder if there is an inadequate seal between the cylinder lining (above) and the cylinder housing?

A weakness, already noted by Richard, is that the one-way valve washer becomes unseated causing the pump to fail.

This had happened again with the Mapalo pump, exacerbated probably by the amount of sand previously pumped through. I found another washer in the kit and glued it to the brass valve base. The drive unit was reassembled, primed and, hey presto - it worked again! The water was much clearer than previously but still a little cloudy.

Tuesday 4 April 2006 - Some tasks have been lined up at Isubilo and there is a storeroom need on the farm for school clothes and shoes (for their SOBIA school project) just like there was at Isubilo a couple of years ago - so its back to making a storage system again from cardboard packing cases and PVA glue ...

You start with a packing case and cut off its ends (complete with 2" flaps all round); then with a second box cut out the side apertures; stick in a new middle panel (from the first box) and stick down all the lid flaps; turn over and stick all the base flaps - viola! (You get 4 middle panels from a box by using the sides also.) The tool boxes used here are pressing down on the glued flaps for about an hour while the PVA glue dries.

Wednesday 5 April 2006 - Got stuck in with the PVA glue ... made the first couple of boxes in the basement outside the storeroom only to discover that they didn't fit through the storeroom door ... doh! (All the boxes already in use in the storeroom were folded flat, taken in and then filled again - so easy to make assumptions!) But no problem ... we needed some of them cut in half anyway for shoe bins (phew!)

Abbie did a little donkey work - Daisy was due to foal real soon and so the stethoscope was applied for a pre-natal check ...

"I still can't hear it!"

I think she licks me!

Thursday 6 April 2006 - Visit to the Kaloko SOBIA project houses and site for the new school.

... one of the three houses having had a new roof and fully renovated to function as a school room until the school is built.

... Abbie stepping out of the old latrine - now rather full - so a new pit has been dug to the left ...

... you can just see a frog and a small rat at the bottom!

... another of the SOBIA houses.

Also visited Father Locking of St John the Baptist Catholic Church and saw the fruit of his skills training programme and workshops. He had a problem with his two India Mk II pumps and wells so immediately got him talking to Gerry.

Sunday 9 April 2006 - We attended church in Kaloko school along with a number of the farm staff ... just like house church 'in the old days'! There were at least four other churches meeting at the same time in different classrooms around the school and one could here singing from all quarters!

Monday 10 April 2006 - Handover of the new storage facility to Josie and Derry of the farm ...

... note the half boxes on top - just right for shoes. The boxes are strong enough to stand on - though not recommended!

Checked with Gerry to check if the Awassa pumps were OK - Francis' pump was not working properly and so arranged to meet up and give Gerry some hands-on maintenance training for the following day.

Tuesday 11 April 2006 - To the SHIP house to meet Gerry and fix the pump at Francis' house next door. We talked about the need for water in Kaloko at the new school site and the SOBIA houses nearby. Gerry was keen to visit those at the farm and perhaps to take the drilling rig to the site at Kaloko.

Francis' pump: discovered that the handle operated too easily and very little water came out. This has happened with the Mapalo pump. So Gerry and I dismantled the top drive unit to discover that the flat washer had come unstuck as before with the other pump. This time there were no spare washers ... so with nothing to lose the damaged remains of the washer was removed and the drive unit reassembled. The thinking being that the brass bush had a very good flush fit to the plastic disc and might still enable a seal on the downstroke, but without the rubber washer ... and it did! So much so that the pump worked more reliably, every stroke, bringing up as much water as before! So Richard, the brass bush doesn't need the inset for the washer (or the washer), making it simpler still!

And then on to the Mapalo pump again in the afternoon, this time I was getting a lift from Tony. The pump was still there but barely working and very stiff. The water was still very cloudy. We dismantled the top drive unit to find the water very muddy/sandy. However the washer was still intact (I had used a lot of glue on it last time)! There was a lot of fine sandy outside the cylinder liner as before, the leather cup washer was clogged and impregnated with grit, the cylinder was very scored. There was nothing more to do than reassemble and leave it. The well was full of sand which had made both the pump and drive units very stiff to operate and quite ineffective. This was no fault of the pump.

Got progressively poorly in the late afternoon, hot and cold, feverish - query malaria, especially as I had forgotten my weekly Larium tablet last Thursday - so to bed very early, no supper. By 10pm it wasn't going away so started an anti-malarial course (one carries a box of Coartem as a matter of course).

Wednesday 12 April 2006 - 5am: took another 4 tablets, "I wonder whether should I go, or should I stay?" - could I make it through a four hour journey in a cramped hot coach, then a ten hour flight the day after? Hmmm - so prepared a list of what to do under 'plan B' (ring up the travel insurance company, arrange a different flight, etc, etc)!

6am: tried the, 'get up, shower, get dressed, see if I'm OK', would help make the decision. The dizziness didn't help, but heh, let's give it a whirl! Tony, one of the farm team, offered to take me to the doctor in town ... we did that and I was getting a bit better ... the doctor was good: blood test, no malaria; urine test, urinary tract infection, symptoms matched, started the antibiotics.

Back to the farm, two hours to go to go back to town to catch the bus to Lusaka! A four hour bus trip and we arrive in Lusaka as the sun is setting ...

Thursday 13 April 2006 - Up at 5am to get the flight home. The taxi driver from yesterday arrived 15 minutes early, then we're on our way to the BA flight to Heathrow.